Table of contents

- Introduction

- Bhopal Gas Tragedy (India, 1984)

- Banqiao Dam Failure (China, 1975)

- Texas City Disaster (USA, 1947)

- Chernobyl Nuclear Disaster (Ukraine, 1986)

- Oppau Explosion (Germany, 1921)

- Minamata Disease (Japan, 1950s)

- Seveso Disaster (Italy, 1976)

- Courrières Mine Disaster (France, 1906)

- Deepwater Horizon Oil Spill (Gulf of Mexico, 2010)

- Rana Plaza Collapse (Bangladesh, 2013)

- Conclusion

Introduction

Industrial accidents, though often preventable, have been responsible for some of the most devastating events in human history. These incidents result in not only the loss of life but also long-term environmental damage, economic upheaval, and social consequences that ripple through generations. From chemical explosions and dam failures to nuclear disasters and building collapses, industrial accidents are stark reminders of the dangers inherent in large-scale operations when safety measures are ignored or compromised.

This blog takes a deep dive into the ten deadliest industrial accidents in history. By exploring the causes and aftermath of these disasters, we’ll uncover how each of them reshaped industries, forced regulatory changes, and left legacies that continue to influence workplace safety standards today.

Bhopal Gas Tragedy (India, 1984)

The Bhopal Gas Tragedy, one of the deadliest industrial accidents in history, unfolded on the night of December 2-3, 1984, in Bhopal, India. A toxic gas leak from the Union Carbide India Limited (UCIL) pesticide plant released methyl isocyanate (MIC) into the air, exposing over 500,000 people to its harmful effects. The immediate death toll was estimated at around 2,000 to 8,000 people, but the long-term effects of the gas exposure raised the total number of deaths to as many as 25,000 over the following years. Hundreds of thousands more suffered from chronic illnesses, respiratory problems, and other debilitating conditions due to the exposure.

Cause of the Disaster:

The leak occurred when water entered a storage tank containing around 42 tons of methyl isocyanate, triggering an exothermic reaction that raised the temperature and pressure inside the tank. The resulting gas cloud spread quickly over nearby densely populated areas. Multiple safety systems that could have contained the leak were either malfunctioning or turned off due to cost-cutting measures.

Immediate Impact:

The effects of the gas were felt almost immediately, with thousands dying within hours from respiratory failure, choking, and pulmonary edema. Hospitals were overwhelmed, and the city’s infrastructure struggled to cope with the scale of the disaster. Those who survived the initial exposure suffered from long-term health effects such as blindness, neurological damage, and organ failure. Children born to exposed mothers also suffered from birth defects.

Legacy:

The Bhopal disaster exposed glaring gaps in industrial safety, particularly in the handling of hazardous materials. The incident led to widespread criticism of Union Carbide’s management and operations, raising questions about corporate responsibility in developing countries. It also highlighted the dangerous intersection of poor regulation, cost-cutting, and inadequate emergency response systems.

In response to the tragedy, India enacted stricter industrial safety laws, and the incident spurred global awareness of the need for proper safety protocols when dealing with toxic chemicals. Internationally, it influenced policies on corporate liability and hazardous chemical management, including the strengthening of the Environmental Protection Act and the establishment of the National Disaster Management Authority in India. Despite the legal actions taken, many victims have long argued that compensation and remediation efforts have been inadequate, and the Bhopal site remains contaminated to this day.

The Bhopal Gas Tragedy remains a chilling reminder of the catastrophic consequences of negligence in industrial operations and continues to be a focal point in discussions about corporate accountability, environmental justice, and worker safety.

Banqiao Dam Failure (China, 1975)

The Banqiao Dam failure, one of the deadliest industrial disasters in history, occurred in Henan Province, China, in August 1975. The dam, originally constructed to control flooding and generate hydroelectric power, collapsed during Typhoon Nina after record rainfall overwhelmed its design capacity. The resulting flood caused a catastrophic domino effect, as 62 other dams also failed, releasing a torrent of water that devastated vast regions downstream. The disaster claimed an estimated 171,000 lives and affected over 11 million people.

Cause of the Disaster:

The Banqiao Dam, built in the 1950s as part of China’s efforts to control flooding on the Huai River, was designed to withstand “1-in-1,000-year” floods. However, Typhoon Nina brought unprecedented rainfall that exceeded these estimates, with some areas receiving as much as a year’s worth of rain in just 24 hours. The extreme rainfall caused water levels to rise far beyond the dam’s capacity, and when sluice gates failed to open in time due to technical issues, the dam collapsed under the immense pressure.

The failure of the Banqiao Dam triggered a chain reaction, causing the collapse of several other dams, unleashing a flood wave that swept through the region. Villages and towns were submerged, homes were destroyed, and thousands were caught in the rushing waters with little warning.

Immediate Impact:

The scale of the disaster was overwhelming. Entire towns were wiped out, and vast areas of farmland were submerged under meters of water. The death toll from the initial flood was estimated at 26,000, but the aftermath was even more deadly, as around 145,000 people died due to disease, famine, and the collapse of infrastructure. Survivors were left without shelter, food, or medical aid, further compounding the crisis.

Legacy:

The Banqiao Dam failure was a closely guarded secret for many years, with the Chinese government not fully disclosing the scale of the disaster until decades later. The tragedy exposed serious flaws in the country’s infrastructure planning, especially in the design and maintenance of large dams. It also highlighted the dangers of over-reliance on ambitious infrastructure projects without proper consideration of extreme weather events and climate unpredictability.

In the years following the disaster, China improved its flood control systems and dam management, implementing stricter monitoring and maintenance protocols. The disaster also prompted a re-evaluation of the risks associated with large-scale dam projects, not only in China but across the world. Engineers and policymakers began to prioritize the need for comprehensive risk assessments and emergency preparedness plans, particularly in regions vulnerable to extreme weather events.

The Banqiao Dam failure remains a sobering example of how natural forces can overwhelm human-made structures and how the consequences of poor planning, maintenance, and emergency response can lead to massive human suffering.

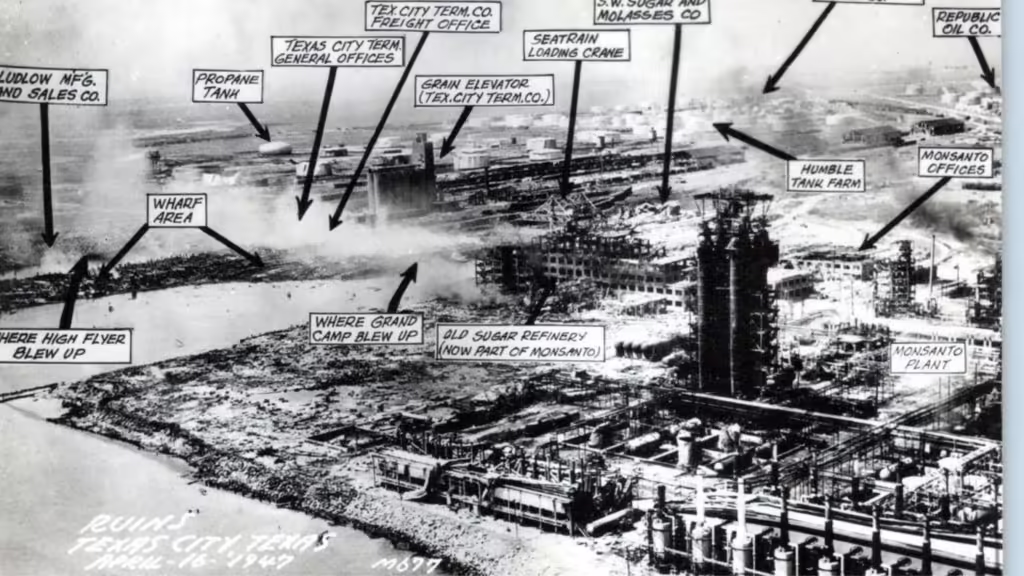

Texas City Disaster (USA, 1947)

The Texas City Disaster, one of the deadliest industrial accidents in U.S. history, occurred on April 16, 1947, when a ship carrying highly explosive cargo of ammonium nitrate caught fire and exploded in the port of Texas City, Texas. The massive explosion killed nearly 600 people, injured thousands, and caused widespread destruction in the surrounding area.

Cause of the Disaster:

The disaster began aboard the French-registered SS Grandcamp, which was docked in Texas City and loaded with approximately 2,300 tons of ammonium nitrate, a chemical used in fertilizers and explosives. The ammonium nitrate had been produced during World War II and was being shipped to Europe for agricultural use. A fire broke out in the ship’s hold, and despite efforts to extinguish it, the fire spread rapidly. The crew attempted to smother the flames by closing the hatches and pumping steam into the cargo holds, but this only exacerbated the problem by creating pressure within the ship.

At 9:12 a.m., the Grandcamp exploded with incredible force, sending shockwaves through the city. The blast was so powerful that it shattered windows as far as 40 miles away and could be felt in Houston, 30 miles to the north. The explosion triggered a chain reaction, as fires broke out in nearby oil refineries, chemical plants, and storage facilities. A second ship, the High Flyer, which was also carrying ammonium nitrate, caught fire and exploded later that night, causing additional damage and casualties.

Immediate Impact:

The explosion killed an estimated 581 people, though the exact number may be higher, as many bodies were never recovered. Among the dead were hundreds of dockworkers, firefighters, and local residents. Entire buildings were flattened, and a 15-foot tidal wave created by the explosion engulfed the docks. Fires raged for days, and the devastation extended across a wide radius, destroying homes, businesses, and infrastructure.

Texas City, a bustling industrial town, was left in ruins. Hospitals were overwhelmed with the injured, and emergency responders from neighboring towns were brought in to help. The scale of the destruction was such that rescue operations took weeks, and many families were left homeless.

Legacy:

The Texas City Disaster remains a key case study in industrial safety, particularly in the handling and transportation of hazardous materials. The magnitude of the explosion exposed serious lapses in safety regulations and procedures related to the storage and shipment of dangerous chemicals like ammonium nitrate. In response, the U.S. government introduced new regulations on the handling and transport of hazardous chemicals. These measures included stricter guidelines for packaging, labeling, and emergency preparedness.

The disaster also led to significant legal changes. Hundreds of lawsuits were filed against the U.S. government under the Federal Tort Claims Act (FTCA), which had been enacted in 1946. The legal proceedings set a precedent for government liability in cases involving negligence. While the lawsuits were initially dismissed, the disaster drew attention to the need for better worker safety standards and corporate accountability.

The Texas City Disaster remains a sobering reminder of the dangers inherent in industrial work, especially when dealing with highly volatile chemicals. The lessons learned from this tragedy shaped modern safety protocols and emergency response practices, helping to prevent similar catastrophes in the future. Today, Texas City has rebuilt, but the memory of the disaster is commemorated each year as a reminder of the importance of industrial safety.

Chernobyl Nuclear Disaster (Ukraine, 1986)

The Chernobyl Nuclear Disaster, one of the worst nuclear accidents in history, occurred on April 26, 1986, at the Chernobyl Nuclear Power Plant near the city of Pripyat in northern Ukraine, which was part of the Soviet Union at the time. A reactor explosion and subsequent fires released massive amounts of radioactive material into the atmosphere, spreading across Europe and affecting millions of people. The disaster not only caused immediate fatalities but also led to long-term health and environmental consequences that are still being dealt with today.

Cause of the Disaster:

The disaster was triggered during a late-night safety test in Reactor 4 of the plant, aimed at determining whether the reactor could continue operating in the event of a power outage. Due to a combination of poor design, inadequate safety protocols, and operator errors, the test went horribly wrong. Operators reduced power levels too quickly, destabilizing the reactor. When they attempted to shut down the reactor completely, a flaw in the reactor’s design caused a sudden and uncontrollable surge in power. This resulted in a massive explosion that blew off the reactor’s roof, exposing the core to the atmosphere.

The explosion released a huge plume of radioactive isotopes, including iodine-131, cesium-137, and strontium-90. The initial blast killed two workers instantly, while 28 more plant workers and firefighters died within a few weeks from acute radiation exposure. The fire in the reactor core continued to burn for 10 days, releasing additional radioactive material into the environment.

Immediate Impact:

The immediate aftermath of the explosion was chaotic. Despite the massive release of radiation, authorities did not immediately evacuate the nearby town of Pripyat, which housed around 49,000 people, many of whom worked at the plant. It wasn’t until 36 hours later that evacuation orders were issued. By then, the residents had already been exposed to dangerous levels of radiation.

Soviet authorities initially downplayed the severity of the disaster, and the international community only became aware of the incident when elevated radiation levels were detected in Sweden, over 1,000 miles away. Eventually, a 30-kilometer (19-mile) exclusion zone was established around the plant, and over 350,000 people were relocated from the affected areas.

Legacy:

The Chernobyl disaster had far-reaching consequences. In terms of human health, the immediate death toll from radiation was 31, but long-term estimates suggest that thousands more may have died from radiation-related illnesses, particularly thyroid cancer, leukemia, and other cancers linked to radiation exposure. The World Health Organization (WHO) and other agencies estimate that the eventual death toll could reach between 4,000 and 93,000 due to the long-term effects of radiation.

The environmental impact was equally devastating. The exclusion zone around Chernobyl remains largely uninhabitable due to high levels of radioactive contamination, and wildlife in the area has been affected for decades. However, the absence of human activity has led to a resurgence of animal populations, creating a kind of unintended nature reserve in the region.

Political and Social Fallout:

Chernobyl also had significant political and social repercussions. The Soviet government’s mishandling of the disaster and the lack of transparency in the days following the explosion contributed to the erosion of trust in the government. The disaster is often cited as one of the events that accelerated the collapse of the Soviet Union in 1991.

Internationally, Chernobyl raised serious concerns about the safety of nuclear power. Many countries reevaluated their nuclear programs, and public opposition to nuclear energy grew. In the decades following the disaster, nuclear safety regulations were strengthened worldwide, and older reactors like those at Chernobyl were either retrofitted with new safety systems or decommissioned.

Environmental and Cleanup Efforts:

The site of the Chernobyl disaster remains a focal point of ongoing environmental remediation. The damaged reactor was encased in a concrete sarcophagus to contain the remaining radioactive material, but over time, this structure began to degrade. In 2016, a new steel containment structure, known as the New Safe Confinement, was placed over Reactor 4 to further reduce radiation leakage and allow for the eventual dismantling of the reactor.

While the area around Chernobyl remains off-limits for human habitation, scientists continue to study the long-term effects of radiation on both the environment and human health. Chernobyl has become a symbol of the potential risks of nuclear power and the catastrophic consequences of inadequate safety measures.

Cultural Impact:

The Chernobyl disaster has also had a lasting impact on global culture, inspiring numerous books, documentaries, films, and television series. The 2019 HBO miniseries Chernobyl brought renewed attention to the disaster, highlighting the human and bureaucratic failures that contributed to the tragedy. The disaster remains a chilling reminder of the immense power—and potential dangers—of nuclear energy when safety protocols are ignored or compromised.

The legacy of Chernobyl is a stark warning of the risks associated with nuclear energy and the devastating consequences of regulatory failure and human error. It reshaped the way the world views nuclear power and remains a pivotal moment in the history of industrial safety and environmental awareness.

Oppau Explosion (Germany, 1921)

The Oppau Explosion, one of the deadliest industrial accidents in early 20th-century Europe, occurred on September 21, 1921, at a chemical plant owned by BASF (Badische Anilin- und Sodafabrik) in Oppau, Germany. The explosion killed around 600 people, injured thousands, and caused widespread destruction in the surrounding area. It was one of the earliest major industrial disasters, highlighting the inherent dangers of large-scale chemical production.

Cause of the Disaster:

The BASF plant in Oppau produced ammonium sulfate and ammonium nitrate fertilizer, which were stored in large silos. The fertilizer mixture, consisting of both explosive and non-explosive components, tended to form solid clumps during storage, making it difficult to handle and transport. To break up the hardened masses, workers regularly used small charges of dynamite, a practice that had been successfully used at the plant for years without incident.

On the morning of September 21, 1921, while attempting to break up another batch of caked fertilizer, workers detonated dynamite as usual. However, this time, the dynamite ignited the ammonium nitrate in the mixture, resulting in a massive explosion. The blast was so powerful that it created a crater 90 meters (300 feet) wide and 20 meters (65 feet) deep, completely destroying the storage silo and much of the surrounding factory.

Immediate Impact:

The explosion killed approximately 600 people instantly, many of whom were factory workers. Thousands more were injured, with some suffering from severe burns, flying debris injuries, or being trapped under collapsed buildings. The force of the explosion was felt up to 300 kilometers (186 miles) away, with reports of windows shattering as far as Frankfurt.

The surrounding town of Oppau was severely damaged, with over 80% of its buildings either destroyed or heavily damaged. Entire residential areas were leveled, and the loss of life was compounded by the fact that many of the town’s residents were factory employees or lived close to the industrial site. The shockwave from the explosion was so immense that it was mistaken for an earthquake in nearby cities.

Legacy:

The Oppau Explosion was a wake-up call for industries dealing with explosive chemicals, particularly ammonium nitrate. Prior to this disaster, the dangers of ammonium nitrate were not fully understood, as the compound had been safely used in fertilizers for years. However, the combination of ammonium nitrate with ammonium sulfate and the use of dynamite to loosen the material created a lethal mixture that was capable of triggering a catastrophic explosion.

Following the Oppau disaster, significant changes were made to the handling and storage of ammonium nitrate. Industries began to develop safer methods for dealing with caked materials and discontinued the use of explosives for breaking up fertilizer blocks. This event also led to a deeper understanding of the explosive properties of ammonium nitrate, which would later play a role in safety measures adopted by the chemical industry worldwide.

In Germany, the disaster spurred stricter safety regulations for chemical plants and increased government oversight of industrial operations. The event also contributed to the establishment of more comprehensive risk management protocols in industries dealing with hazardous materials.

Broader Implications:

The Oppau Explosion was an early example of the risks associated with large-scale industrialization and the use of complex chemical processes. While the explosion was caused by a combination of human error and insufficient knowledge of the materials involved, it emphasized the need for better safety practices in the rapidly growing chemical industry of the early 20th century.

The incident had a lasting impact on industrial safety, particularly in Europe, where it raised awareness of the dangers posed by improper storage and handling of chemicals. It also served as a precursor to later industrial accidents involving ammonium nitrate, such as the Texas City Disaster in 1947, reinforcing the lessons learned about the hazards of this common industrial material.

The Oppau Explosion remains one of the most tragic industrial accidents in history, serving as a reminder of the importance of rigorous safety protocols and the potential for catastrophic consequences when handling volatile chemicals. The disaster’s legacy can still be seen in modern industrial practices, where safety and risk management have become central to preventing similar tragedies.

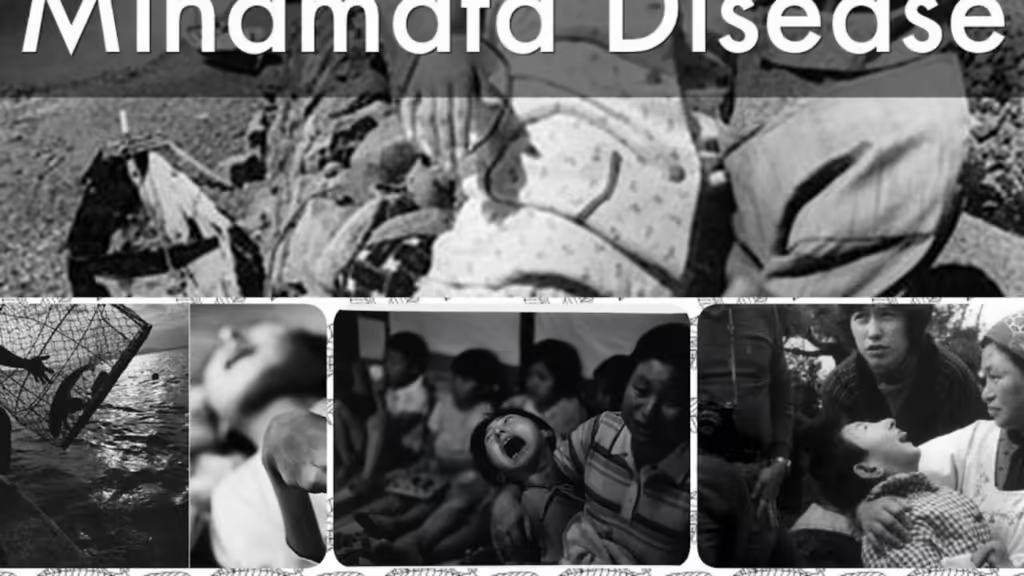

Minamata Disease (Japan, 1950s)

Minamata Disease, a devastating industrial pollution disaster, emerged in the 1950s in the small coastal town of Minamata, Japan. This neurological syndrome was caused by severe mercury poisoning resulting from industrial wastewater containing methylmercury being discharged into Minamata Bay by the Chisso Corporation. The mercury accumulated in marine life, which was a primary food source for the local population. Over time, residents who consumed contaminated fish and shellfish developed debilitating symptoms. The disaster became one of the most infamous cases of environmental pollution in the world and a major public health crisis in Japan.

Cause of the Disaster:

Between 1932 and 1968, the Chisso Corporation, a chemical company, released untreated industrial waste containing methylmercury into Minamata Bay. The waste came from the company’s acetaldehyde production plant, where mercury compounds were used as catalysts. Methylmercury, a highly toxic compound, entered the aquatic ecosystem and bioaccumulated in fish and shellfish, which were a staple of the local diet.

Initially, the cause of the illness that plagued the community was unknown. Residents, fishermen, and their families began showing symptoms such as numbness in the hands and feet, muscle weakness, loss of vision, impaired speech, and uncontrollable body movements. In severe cases, victims fell into comas or died, often after suffering from intense convulsions.

Immediate Impact:

The disease was first officially identified in 1956 after doctors noticed a pattern of neurological disorders in patients from the area. However, it took years before the cause was traced back to mercury poisoning from industrial pollution. At least 900 people died from the disease, and over 2,000 were officially diagnosed with Minamata Disease, although many more were likely affected but remained undiagnosed.

The impact on the local community was profound. Entire families were affected by the disease, and many victims were left with lifelong disabilities. Infants born to mothers who had consumed contaminated fish during pregnancy suffered from congenital Minamata Disease, showing severe deformities, mental retardation, and other neurological impairments.

Legacy:

Minamata Disease brought global attention to the dangers of industrial pollution and corporate negligence. The Chisso Corporation denied responsibility for years, and local authorities initially downplayed the severity of the issue. It wasn’t until a series of protests, legal battles, and increasing public pressure that the company admitted its role in causing the disease. In 1968, the Japanese government officially recognized the cause of Minamata Disease as mercury poisoning from Chisso’s wastewater.

Legal battles for compensation stretched on for decades. Many victims received financial settlements, but the amounts were often deemed inadequate given the severity of their suffering. In 1973, the Japanese courts ordered Chisso to pay substantial compensation to the victims, and the company was required to clean up the bay. However, the environmental damage had already been done, and it took years to begin the process of restoring the affected ecosystem.

Environmental and Social Impact:

The Minamata disaster significantly changed how Japan and the world approached environmental pollution and industrial waste management. It prompted stricter environmental regulations in Japan and influenced the creation of the country’s Environmental Agency in 1971 (now the Ministry of the Environment). The lessons learned from the Minamata case have had a lasting impact on global discussions about corporate responsibility, environmental justice, and the health impacts of industrial activities.

For the affected community, the legacy of Minamata Disease remains a painful chapter in their history. Many survivors still live with the physical and psychological scars of the disaster. Annual memorials are held in Minamata to honor the victims and remind future generations of the importance of environmental stewardship.

Global Significance:

The Minamata case has become a symbol of industrial pollution’s dangers, particularly in developing countries where environmental regulations may still be weak or unenforced. It has been referenced in international discussions on environmental health, corporate accountability, and human rights. The Minamata Convention on Mercury, adopted in 2013, is a global treaty that aims to reduce mercury pollution worldwide, and its very name is a tribute to the victims of the Minamata disaster.

Minamata Disease stands as one of the most tragic examples of the harm caused by unchecked industrial pollution. Its legacy continues to influence environmental policy and public health, reminding the world of the critical need to balance industrial progress with environmental protection and human well-being.

Seveso Disaster (Italy, 1976)

The Seveso Disaster was a chemical accident that occurred on July 10, 1976, at a chemical manufacturing plant in the small town of Seveso, near Milan, Italy. The incident led to the release of a highly toxic cloud of dioxin (TCDD), a byproduct of the herbicide and pesticide manufacturing process, which spread over the surrounding residential areas. The disaster exposed thousands of people to dangerous levels of contamination, prompting one of the most significant industrial pollution responses in Europe and resulting in stricter environmental regulations.

Cause of the Disaster:

The incident occurred at a chemical plant operated by ICMESA, a subsidiary of the Swiss-based pharmaceutical company Hoffmann-La Roche. The plant was producing trichlorophenol, a chemical used in disinfectants and herbicides. During routine operations, a reactor overheated due to a malfunction, and a safety valve opened, releasing a cloud of chemicals, including dioxin (TCDD), into the atmosphere.

Dioxin is an extremely toxic compound known for its long-lasting presence in the environment and its severe health effects, including cancer, reproductive harm, and developmental issues. The wind carried the toxic cloud over the nearby towns, most notably Seveso, leading to widespread contamination of the area.

Immediate Impact:

Although no one died immediately from the exposure, the effects of the dioxin contamination were profound. Within days, vegetation in the affected area began to wither and die, and farm animals suffered from severe illnesses, with over 3,000 animals dying within days. As a precautionary measure, authorities culled over 80,000 animals to prevent the spread of contamination through the food chain.

Local residents began to develop skin lesions, particularly a severe form of acne known as chloracne, caused by dioxin exposure. Hundreds of people, especially children, were affected by these skin disorders. Authorities quickly evacuated over 600 residents from the most contaminated zones and advised thousands more to avoid contact with the environment.

Despite the clear signs of contamination, initial government responses were slow, and the scale of the disaster was downplayed in its early stages. However, as the extent of the contamination became clear, the Italian government declared a state of emergency and launched a large-scale environmental and medical response.

Legacy:

The Seveso Disaster led to the evacuation of thousands of people, and a large swath of land, around 15 square kilometers, was declared uninhabitable. The most heavily contaminated areas were fenced off, and a major decontamination and cleanup operation was undertaken. Soil was removed and treated, contaminated buildings were demolished, and protective barriers were erected to contain the spread of dioxin.

Over time, the site of the disaster was transformed into a public park, Parco Naturale Bosco delle Querce, symbolizing the area’s recovery from the disaster. However, the long-term health impacts on residents were more difficult to assess. While immediate health effects like chloracne were visible, concerns about long-term consequences, such as cancer and reproductive issues, persisted for decades. Studies on the health of Seveso residents continued for years after the event, showing elevated cancer rates and other health problems, though definitive conclusions about the long-term effects of dioxin exposure were difficult to establish.

The Seveso Directive and Environmental Regulation:

The Seveso Disaster had a major influence on European environmental and industrial safety regulations. In 1982, the European Community introduced the Seveso Directive, a set of safety rules for industrial activities involving hazardous substances. The directive required companies to adopt stronger safety protocols, improve emergency planning, and notify authorities of any potential risks related to dangerous substances.

The Seveso Directive has since been revised multiple times to reflect advancements in industrial safety and expand its scope. Today, it is one of the cornerstones of European environmental law, ensuring that accidents like Seveso are less likely to occur and that the public is better protected in the event of industrial disasters.

Global Influence:

The Seveso Disaster not only influenced European regulations but also shaped global conversations about industrial safety, toxic waste management, and the need for corporate accountability in environmental disasters. It highlighted the potential dangers of chemical manufacturing, especially when safety measures fail, and underscored the importance of emergency preparedness.

Seveso also contributed to the growing awareness of the risks posed by dioxins, leading to stricter global controls on the production and disposal of chemicals that produce these toxic byproducts. The disaster’s legacy is felt in environmental policies around the world, which aim to prevent industrial pollution from harming human health and the environment.

The Seveso disaster is a stark reminder of the risks associated with the production and handling of hazardous chemicals. It spurred regulatory changes that improved industrial safety in Europe and worldwide, serving as a benchmark for how societies should respond to chemical disasters and protect their citizens from toxic exposure.

Courrières Mine Disaster (France, 1906)

The Courrières Mine Disaster, which occurred on March 10, 1906, in northern France, remains one of the deadliest mining disasters in European history. The tragedy unfolded at the Courrières coal mine, located in the Pas-de-Calais region, and resulted in the deaths of 1,099 miners, profoundly impacting mining safety regulations and labor rights in France and beyond.

Cause of the Disaster:

The disaster was triggered by a series of explosions caused by the ignition of methane gas, a common hazard in coal mining. On the day of the disaster, methane accumulated in the mine shafts due to inadequate ventilation and poor safety practices. The initial explosion occurred around 6:30 p.m. and was followed by a second, more powerful blast that ripped through the mine, causing extensive damage to the tunnels and trapping many miners underground.

At the time of the disaster, approximately 1,400 workers were in the mine. The explosions led to the collapse of several tunnels, trapping miners in the dark, smoke-filled shafts. Rescue efforts began immediately, but the scale of the disaster and the hazardous conditions hindered progress.

Immediate Impact:

The Courrières Mine Disaster had a devastating immediate impact. Of the 1,400 miners inside the mine, only 303 survived. The loss of life was catastrophic, with entire families devastated by the deaths of fathers, brothers, and sons. The explosions not only killed miners but also injured many others, with survivors suffering from burns, smoke inhalation, and injuries sustained during the explosions.

The rescue operations were perilous and slow, with rescuers facing dangerous conditions, including the risk of further explosions and toxic gas exposure. Despite the heroic efforts of rescue teams, the extensive damage and the sheer number of victims made it challenging to recover bodies. Many of the miners remained trapped underground for days, and it took weeks to fully recover all the remains.

Legacy:

The Courrières Mine Disaster sent shockwaves through France and highlighted the dire conditions miners faced in the early 20th century. In the aftermath of the disaster, there was an increased awareness of the need for improved safety regulations and labor rights in the mining industry. Public outcry over the tragedy led to demands for better working conditions, enhanced safety measures, and accountability for mining companies.

In response, the French government implemented stricter mining safety regulations, including requirements for better ventilation, regular inspections, and the installation of safety equipment. The disaster also fueled the growth of labor unions in the mining sector, as workers organized to advocate for safer conditions and fairer treatment. Miners increasingly recognized the need to collectively push for their rights and safety, leading to significant labor movements across the country.

Cultural and Historical Significance:

The Courrières Mine Disaster has been memorialized in various ways, from monuments and memorial services to literature and art. It serves as a poignant reminder of the risks associated with industrial labor and the importance of worker safety.

The disaster also sparked broader discussions about industrialization and its human cost. It became a rallying point for labor rights activists and safety advocates, leading to a greater emphasis on protecting workers in hazardous industries worldwide.

The Courrières Mine Disaster remains a critical chapter in the history of mining safety and labor rights. Its legacy is a testament to the sacrifices of miners and the ongoing struggle for safer working conditions in industries where human lives are often at risk due to negligence and insufficient regulations. The lessons learned from this tragedy continue to inform mining practices and labor laws today, emphasizing the necessity of prioritizing worker safety in all industrial endeavors.

Deepwater Horizon Oil Spill (Gulf of Mexico, 2010)

The Deepwater Horizon Oil Spill, one of the largest environmental disasters in U.S. history, occurred on April 20, 2010, when the Deepwater Horizon drilling rig, operated by Transocean and owned by BP (British Petroleum), experienced a catastrophic blowout. The incident resulted in the release of approximately 4.9 million barrels of crude oil into the Gulf of Mexico over 87 days, severely impacting marine ecosystems, coastal communities, and economies in the region.

Cause of the Disaster:

The disaster was triggered by a series of equipment failures and poor decision-making related to the drilling operations. On the day of the blowout, workers had just completed cementing operations on the well, but critical safety measures were either ignored or inadequately executed. The blowout preventer (BOP), a critical safety device designed to seal the well in case of a pressure surge, failed to activate properly, allowing high-pressure oil and gas to surge uncontrollably to the surface.

Following the blowout, the rig caught fire, resulting in the loss of 11 crew members’ lives and causing significant injuries to others. The rig ultimately sank, leaving the wellhead exposed and gushing oil uncontrollably into the Gulf.

Immediate Impact:

The immediate impact of the spill was devastating. Oil began to spread across the Gulf of Mexico, creating a massive slick that extended over thousands of square miles. The spill severely affected marine life, including fish, dolphins, and sea turtles, leading to immediate and long-term ecological consequences. The oil contaminated beaches, marshlands, and critical habitats, disrupting local ecosystems and impacting wildlife populations.

The spill also had dire consequences for local economies dependent on fishing and tourism. Fishermen faced closures of fishing areas due to contamination, and tourism in affected coastal regions plummeted as beaches were fouled by oil. Local businesses suffered severe financial losses, and many residents experienced significant economic hardship.

Response Efforts:

In the wake of the disaster, a massive response effort was launched involving federal, state, and local agencies, along with BP and various non-profit organizations. Efforts included deploying booms to contain the oil, using dispersants to break down the oil, and undertaking beach clean-up operations. Thousands of personnel were mobilized for clean-up efforts, and various techniques were employed to mitigate the spill’s impact.

However, the response was widely criticized for being poorly coordinated and inadequate, particularly in the early days of the disaster. Many experts argued that the use of chemical dispersants raised concerns about their environmental impact and effectiveness in combating the spill.

Long-Term Environmental Impact:

The environmental consequences of the Deepwater Horizon Oil Spill were profound and long-lasting. Studies revealed significant damage to marine and coastal ecosystems, with ongoing impacts on fish populations, marine mammals, and birds. The spill also affected the health of marshlands and wetlands, crucial for biodiversity and as buffers against storm surges.

Research into the spill’s long-term effects continues, with many scientists warning that the repercussions for marine life and ecosystems may persist for decades. The disaster highlighted the vulnerabilities of marine environments to industrial activities and underscored the importance of protecting these ecosystems from similar incidents.

Legacy and Changes in Regulations:

The Deepwater Horizon Oil Spill prompted widespread public outrage and scrutiny of the oil and gas industry. It led to numerous lawsuits, with BP facing significant financial penalties and compensation claims totaling tens of billions of dollars. The company ultimately agreed to a record $20.8 billion settlement with the U.S. government in 2015, the largest environmental settlement in U.S. history.

In response to the disaster, significant changes were made to oil drilling regulations and safety practices. The U.S. government implemented stricter regulations regarding offshore drilling, including enhanced safety protocols for blowout preventers and more rigorous inspections of drilling operations. The incident prompted the establishment of the Bureau of Safety and Environmental Enforcement (BSEE) to oversee offshore drilling safety.

The Deepwater Horizon disaster also raised global awareness about the risks associated with offshore drilling and the need for improved safety standards across the oil and gas industry. It sparked conversations about energy policy, the environmental impacts of fossil fuels, and the urgent need for a transition to more sustainable energy sources.

The Deepwater Horizon Oil Spill serves as a stark reminder of the potential consequences of industrial negligence and the fragility of marine ecosystems. Its legacy continues to influence regulatory practices and public discourse on environmental protection, energy sustainability, and corporate responsibility. The disaster remains a significant chapter in the ongoing story of humanity’s relationship with the environment and the need for vigilance in safeguarding our natural resources.

Rana Plaza Collapse (Bangladesh, 2013)

The Rana Plaza collapse on April 24, 2013, in Dhaka, Bangladesh, stands as one of the deadliest industrial disasters in history, highlighting the grave risks associated with the global garment industry. The eight-story building, which housed several garment factories, a bank, and shops, collapsed in the morning hours, resulting in the tragic loss of over 1,100 lives and injuring more than 2,500 people. The disaster not only underscored the dire conditions faced by garment workers but also prompted a global reevaluation of labor practices and factory safety standards.

Cause of the Disaster:

Rana Plaza was constructed with substandard materials and without proper safety assessments. In the days leading up to the collapse, large cracks were observed in the building’s structure, leading some workers to express concerns about their safety. Despite these warnings, factory owners and local authorities insisted that the building was safe, and workers were ordered to return to work. The pressure to meet production deadlines and maintain profit margins often led to ignoring safety protocols and worker rights.

On the morning of April 24, the building experienced a catastrophic failure, collapsing in seconds. The collapse was sudden, trapping thousands of workers under the rubble. Rescue operations began immediately, but the scale of the disaster made the recovery process perilous and challenging.

Immediate Impact:

The immediate aftermath of the collapse was devastating. Rescue teams worked tirelessly to locate survivors and recover bodies from the debris. Many were trapped for days, and the grim reality of the disaster became evident as the death toll rose. Families faced immense loss, and the community was left to grapple with the tragedy.

The incident drew international attention, leading to widespread outrage over the unsafe working conditions in Bangladesh’s garment factories. The global garment industry, which relies heavily on cheap labor in countries like Bangladesh, faced scrutiny regarding its labor practices and the ethical implications of sourcing clothing from such factories.

Global Response and Reforms:

The Rana Plaza disaster prompted a significant global response, leading to demands for better labor rights, improved safety standards, and greater accountability for clothing brands sourcing from Bangladesh. Several initiatives emerged to address the systemic issues within the garment industry:

- Accord on Fire and Building Safety in Bangladesh: Established in the wake of the disaster, this legally binding agreement between brands and trade unions aimed to improve safety in the Bangladeshi garment industry. It required regular inspections of factories and mandated improvements in safety conditions.

- Alliance for Bangladesh Worker Safety: Similar to the Accord, this initiative was formed by North American retailers to promote worker safety and rights in the garment sector.

- Increased Transparency: Many brands began to publish their supplier lists and adopt more transparent sourcing practices, enabling consumers to make informed choices about the clothing they purchase.

- Strengthened Labor Rights: The disaster sparked discussions about labor rights and fair wages for garment workers. Activists and organizations pushed for stronger labor laws in Bangladesh and better protections for workers’ rights.

Ongoing Challenges:

While the Rana Plaza collapse led to significant changes, challenges remain in ensuring that these reforms are effectively implemented. Reports indicate that while some improvements have been made in safety standards, many factories still operate under dangerous conditions, and workers continue to face exploitation and poor wages.

The legacy of the Rana Plaza disaster endures as a crucial chapter in the fight for workers’ rights and safety in the global garment industry. It serves as a poignant reminder of the need for vigilance in monitoring labor practices and ensuring that ethical standards are upheld in supply chains.

Cultural Impact and Memorialization:

The tragedy also inspired art, literature, and activism focused on labor rights and the impact of globalization on vulnerable workers. The Rana Plaza site has been memorialized, and annual events commemorate the victims, keeping their stories alive and reminding the world of the human cost behind fast fashion.

The Rana Plaza collapse is a powerful symbol of the struggles faced by workers in the global economy and the ongoing fight for dignity, safety, and justice in labor practices. Its legacy continues to resonate within discussions on ethical consumption, corporate responsibility, and the need for systemic change in the garment industry. The disaster stands as a clarion call for consumers, brands, and governments to prioritize the safety and rights of workers in all sectors.

Conclusion

The ten deadliest industrial accidents in history serve as stark reminders of the catastrophic consequences that can arise from negligence, inadequate safety measures, and a disregard for human life. Each disaster—from the Bhopal Gas Tragedy to the Rana Plaza Collapse—has left an indelible mark on the affected communities and has significantly influenced industry regulations, safety practices, and labor rights globally.

These events have prompted essential reforms and increased awareness about the importance of prioritizing worker safety and environmental protection. The legislation resulting from these tragedies, such as the Seveso Directive and the Accord on Fire and Building Safety, reflects a growing recognition of the need for accountability and responsibility within industries. However, despite progress, many challenges persist, and the lessons learned from these disasters must continue to drive change.

The enduring legacy of these accidents emphasizes the critical need for vigilance, proactive safety measures, and ethical practices in industrial operations. As consumers, policymakers, and corporations, we share a collective responsibility to advocate for the well-being of workers and the environment, ensuring that the horrors of the past are not repeated.

Ultimately, the fight for safer working conditions and environmental integrity is ongoing. By remembering these tragedies and honoring the lives lost, we can work towards a future where industrial advancement does not come at the expense of human life and well-being. Through continuous dialogue, reform, and ethical practices, we can strive to create safer, fairer workplaces for generations to come.

Also Read: A World Drowning in Waste: How Pollution is Destroying Our Ecosystems.